AI-Powered Inspection Solutions for Every Industry

Discover our intelligent inspection solutions, tailored to enhance accuracy, efficiency, and compliance across diverse industries.

AI Visual Inspection App for Manufacturing

Detect cracks, dents, and defects using AI-powered inspection software for faster, accurate production-line inspections.

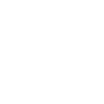

Home Inspection App

Perform detailed home inspections with AI-powered inspection software to assess structural integrity, safety, and compliance.

AI Property and Infrastructure Inspection App

Analyze walls, roofs, and infrastructure with AI-powered anomaly detection using high-resolution imaging and video.

AI Safety and Compliance Inspection App

Monitor workplace hazards and PPE compliance with real-time alerts using AI visual inspection systems.

AI Quality Assurance App

Ensure product quality meets industry standards with automated checks and deep learning for visual inspection.

AI Environmental Monitoring App

Track waste, water quality, and pollution using intelligent inspection solutions for real-time compliance monitoring.

AI Vehicle and Fleet Inspection App

Check tire condition, undercarriage damage, and performance metrics with AI inspection app development.

Key Features of Our AI-Powered Inspection Platform

Our AI inspection platform integrates cutting-edge technology for real-time, accurate, and scalable solutions.

Advantages of AI-Powered Inspection Solutions

Explore the essential capabilities and advantages of deploying our cutting-edge AI inspection software solutions:

1

AI-Driven Time & Cost Reduction

The system uses AI to automate core inspection workflows and optimize team routing. With advanced AI automation services, this eliminates manual paperwork and speeds up on-site digital inspections, resulting in substantial savings on labor and administrative overhead. This strategic automation immediately boosts operational efficiency and throughput.

The platform continuously analyzes workflow patterns to improve scheduling and task prioritization. Teams operate at peak efficiency, inspections remain accurate, and resources are fully optimized. This approach reduces operational costs without compromising inspection quality, allowing businesses to maximize productivity and achieve faster inspection cycles consistently.

2

Timestamped Visual Data Integrity

The software captures high-resolution images and videos with secure, AI-verified timestamps and geotags. This functionality ensures all visual evidence is irrefutable and fully traceable during audits. This enhanced data integrity dramatically reduces disputes and builds a reliable, transparent inspection history for every asset.

A tamper-proof digital record preserves metadata for each image and video. This ensures accountability, strengthens compliance, and builds trust among stakeholders. Teams can confidently access auditable inspection records anytime, ensuring complete reliability and transparency for regulatory, client, or internal reporting requirements.

3

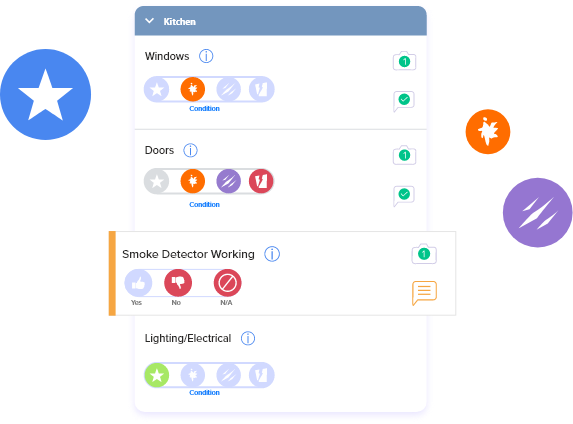

Remote AI-Powered Assessments

The integrated AI engine processes live streams from mobile devices or fixed cameras, enabling AI specialists to conduct accurate asset evaluations remotely. This capability minimizes travel costs and time, allowing for swift, high-quality inspection of large or distant sites without requiring physical presence.

Real-time AI annotations and automated defect detection provide actionable insights instantly. Remote teams can make informed, fast decisions with precision equal to on-site inspections. Operational agility improves, ensuring consistent evaluation standards and reducing delays in inspection reporting and decision-making processes.

4

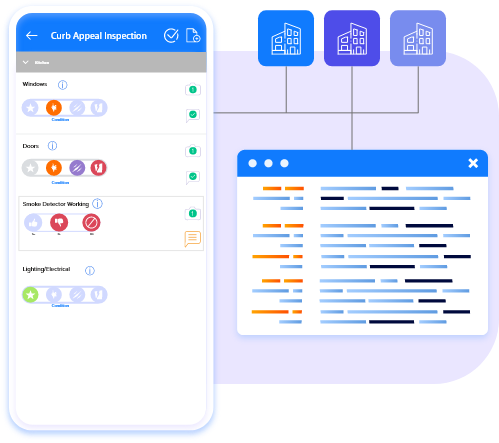

Smart Delegation & Scalability

The platform utilizes AI for intelligent task delegation based on workload and required expertise, ensuring optimal resource allocation. The system easily scales across thousands of assets, new teams, and global locations, accommodating rapid business growth without introducing complex management overhead.

Performance monitoring balances assignments to maintain inspection quality. Teams operate consistently even as project scope grows, allowing businesses to scale operations smoothly while maintaining high standards and minimizing management complexity across distributed inspection projects.

5

Centralized Predictive Dashboard

A unified dashboard uses AI to analyze historical inspection trends and operational data. This predictive capability identifies recurring issues and forecasts potential equipment failures, moving your quality control from reactive flaw detection to proactive, preventive asset maintenance and management.

Custom alerts and actionable insights help managers prioritize inspections efficiently. Resources are allocated intelligently, reducing downtime and improving operational productivity. Decision-making becomes faster and more accurate, increasing safety, reliability, and consistency in inspection processes across all assets.

6

Auto-Generated Quality & Compliance Reports

The system automatically generates structured, comprehensive reports, including defect visuals and regulatory compliance logs. This ensures swift delivery of transparent documentation, minimizing administrative lag and guaranteeing that all stakeholders have access to accurate, audit-ready data instantly.

Reports can be shared seamlessly across internal systems, clients, or regulatory authorities. Workflow automation reduces errors, accelerates decision-making, and strengthens collaboration while maintaining full compliance. Teams can access transparent, reliable reporting for inspections, audits, or operational reviews efficiently.

7

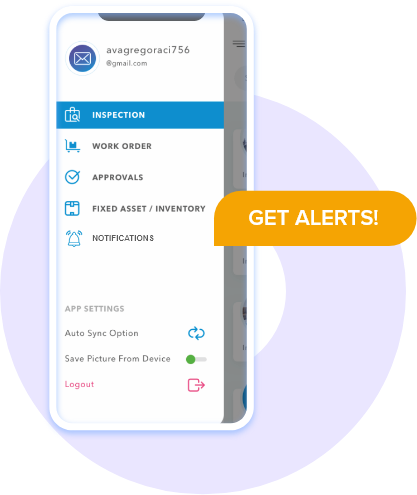

AI-Secured Remote Access with Enterprise Control

The solution guarantees secure, AI-authenticated remote access with enterprise-grade features. Leveraging Single Sign-On (SSO) and granular, role-based permissions, the platform ensures flawless, AI inspection app development and strict data governance across your entire organization.

Advanced encryption and real-time activity monitoring protect sensitive inspection data from unauthorized access. Teams can collaborate globally with confidence, adhere to compliance standards, and maintain enterprise control over inspection workflows, ensuring both security and operational efficiency.

Why Choose Amplework’s AI Inspection Solutions?

As a leading AI development agency, Amplework is trusted by enterprises for the powerful advantages:

Adaptive Compliance Framework

Configure Amplework’s AI to meet unique standards, guaranteeing instant, measurable audit readiness and risk reduction.

Defect Recognition

Deploy custom AI models that learn your product’s specific flaws, improving quality control precision instantly.

Customized Workflow Automation

Implement AI to tailor workflows precisely, enabling immediate cost reduction and increased throughput.

Scalable Custom Deployment

Rapidly integrate and scale Amplework’s solution globally, driving immediate, company-wide operational consistency.

Frequently Asked Questions

Next-Gen AI Inspection App Development

Amplework delivers AI-driven inspection app solutions that enhance accuracy, speed, and efficiency. With cutting-edge AI technology and our expertise in computer vision app development, we automate quality control, reduce errors, and provide scalable, secure solutions to meet your business’s unique inspection needs.

AI-powered inspection solutions use artificial intelligence (AI) and machine learning to automate the inspection process. These systems analyze images or data from sensors to identify defects, ensure quality, and monitor performance, all in real-time. Essentially, they act like a smart, efficient quality control team.

AI inspection systems capture images or data using cameras and sensors. The AI algorithms then analyze this data, looking for patterns, defects, or anomalies. These systems are trained to recognize what’s considered “normal” or “acceptable,” flagging any discrepancies for further review.

Industries that require strict quality control, like manufacturing, automotive, aerospace, electronics, and food production, benefit greatly from AI inspection systems. These systems help improve efficiency, reduce human error, and ensure high standards are maintained.

AI systems offer several advantages, including faster, more consistent inspections and the ability to work continuously without fatigue. They’re highly accurate and can spot defects that might be missed by the human eye. Plus, they provide real-time feedback, allowing for quicker corrective actions.

An AI inspection system is trained using labeled images or sensor data that highlight defects. It learns patterns of normal and faulty conditions, and you can use professional AI model training services to achieve higher accuracy and continuous improvement.

Yes, most AI inspection systems are designed to be easily integrated with existing manufacturing or production systems. They can connect to other equipment, share data, and provide insights that help streamline operations and improve overall efficiency.