How AI Predictive Maintenance Cuts Infrastructure Failures by 73%

Introduction

Infrastructure failures cost industries billions of dollars annually. Unplanned downtime in manufacturing leads to substantial production losses, while critical infrastructure failures in utilities, transportation, and energy create cascading economic impacts. Traditional reactive maintenance fixes problems after failures occur, while preventive maintenance wastes resources servicing equipment that doesn’t need attention. AI predictive maintenance changes this equation entirely, reducing infrastructure failures by up to 73% while cutting maintenance costs by 25-40%.

This blog explains AI predictive maintenance, how it cuts infrastructure failures by 73%, boosts efficiency across sectors, the key technologies involved, best implementation practices, and measurable business ROI.

Understanding AI Predictive Maintenance

AI predictive maintenance uses machine learning to identify potential equipment failures before they occur, enabling proactive action and reducing unplanned downtime. Unlike traditional maintenance approaches, it continuously analyzes sensor data, operational patterns, and environmental conditions to detect early warning signs that are often missed by manual monitoring.

How It Works: Sensors collect real-time data such as temperature, vibration, pressure, and energy usage. Machine learning, based predictive maintenance analytics compares this data with historical failure patterns to identify anomalies. When risks are detected, maintenance teams receive alerts with likely failure causes and recommended actions.

The Transformation: By adopting predictive maintenance, organizations move from reactive repairs to planned interventions, addressing issues during scheduled maintenance windows instead of costly emergency downtime.

Predictive Maintenance Benefits Across Sectors

Manufacturing: Maximizing Uptime

Challenge: Production line equipment failures halt operations, missing deadlines and lost revenue.

Solution: Equipment failure prediction analyzes machine health continuously, scheduling maintenance during planned downtime rather than causing unplanned stops.

Results: 40-60% reduction in downtime, 25-35% lower maintenance costs, 20-30% longer equipment lifespan through optimal maintenance timing.

Example: An automotive manufacturer used vibration and thermal monitoring on assembly robots. The system predicted bearing failures 2–3 weeks early, reducing unplanned production stops by 65%.

Energy & Utilities: Preventing Critical Failures

Challenge: Infrastructure failures in power generation, transmission, or water systems create public safety risks and economic disruptions.

Solution: Smart maintenance systems monitoring transformer health, turbine performance, and distribution network conditions identify degradation patterns indicating imminent failures.

Results: 50-70% reduction in catastrophic failures, improved grid reliability, reduced emergency repair costs, enhanced public safety.

Example: A utility company used AI-based monitoring on 5,000 transformers, predicting failures months in advance. This cut transformer failures by 73% and saved $50 million in emergency replacements.

Transportation: Enhancing Safety and Reliability

Challenge: Vehicle and infrastructure failures cause accidents, delays, and expensive emergency repairs.

Solution: AI maintenance solutions analyze vehicle component health, track infrastructure wear, and predict maintenance needs, optimizing fleet uptime and safety.

Results: 35-55% reduction in vehicle breakdowns, 20-40% lower maintenance costs, improved safety records.

Example: A transit authority used predictive maintenance to monitor engines, brakes, and electrical systems, reducing roadside breakdowns by 58% and improving on-time performance by 32%.

Key Technologies Powering Predictive Maintenance

AI predictive maintenance relies on advanced technologies to prevent equipment failures. This section covers machine learning, IoT sensors, and analytics platforms, and how they enable early issue detection and real-time equipment monitoring.

Machine Learning Algorithms

Predictive maintenance analytics leverage multiple ML techniques:

- Anomaly Detection: Identifying deviations from normal operating patterns, indicating developing issues.

- Regression Models: Predicting remaining useful life (RUL) of components based on degradation patterns.

- Classification Models: Categorizing failure types enabling targeted interventions.

- Deep Learning: Processing complex sensor data patterns, detecting subtle failure indicators.

IoT Sensors and Data Collection

Smart maintenance systems depend on comprehensive data collection:

- Vibration Sensors: Detecting bearing wear, alignment issues, and mechanical degradation.

- Thermal Cameras: Identifying overheating, insulation breakdown, and electrical issues.

- Acoustic Monitoring: Detecting leaks, cavitation, and mechanical anomalies.

- Performance Metrics: Tracking efficiency, output quality, and energy consumption patterns.

Predictive Analytics Platforms

Modern AI maintenance solutions integrate data collection, analysis, and action recommendation:

- Real-Time Processing: Analyzing streaming sensor data, detecting issues as they develop.

- Visualization Dashboards: Presenting equipment health status, failure predictions, and maintenance recommendations.

- Work Order Integration: Automatically generates maintenance tasks when intervention is required.

- Historical Analytics: Identifying patterns across equipment fleets, optimizing maintenance strategies.

Also Read : AI Agent Observability Best Practices for Reliable and Compliant Systems

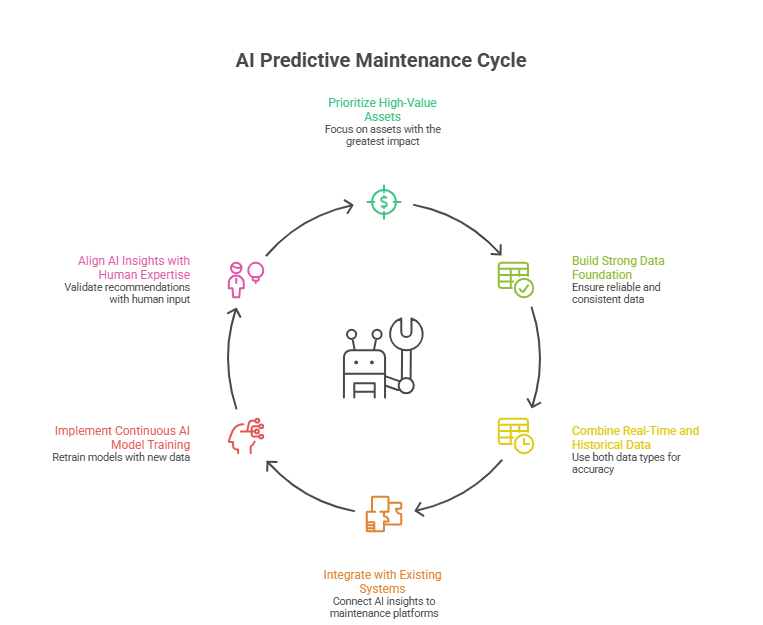

Best Practices for Implementing AI Predictive Maintenance

Successful AI predictive maintenance depends on strong data foundations, system integration, and continuous optimization. These best practices help enterprises reduce failures, improve asset reliability, and maximize ROI.

1. Prioritize High-Value Assets

Begin with infrastructure assets where failures cause the highest operational or financial impact. This ensures measurable ROI early in the implementation.

2. Build a Strong Data Foundation

Reliable predictive maintenance starts with quality data. Standardize IoT sensor inputs, clean historical maintenance records, and ensure data consistency across systems.

3. Combine Real-Time and Historical Data

Use both streaming sensor data and past failure patterns to enable accurate anomaly detection and remaining useful life predictions.

4. Integrate with Existing Maintenance Systems

Integrate AI insights with CMMS and work order platforms to ensure predictions translate directly into maintenance actions without disrupting workflows.

5. Implement Continuous AI Model Training

Once systems are integrated, continuously train and retrain AI models using new operational data. Ongoing AI model training improves accuracy, adapts to asset aging, and reduces false alerts.

6. Align AI Insights with Human Expertise

Maintenance teams should validate AI recommendations and provide feedback. This human-in-the-loop approach strengthens trust and improves long-term performance.

ROI and Business Impact

Predictive maintenance benefits deliver compelling financial returns:

1. Reduced Downtime: 40-60% decrease in unplanned outages, translating to millions in avoided production losses.

2. Lower Maintenance Costs: 25-40% reduction through optimized scheduling, preventing catastrophic failures requiring expensive emergency repairs.

3. Extended Asset Life: 20-30% longer equipment lifespan through optimal maintenance timing, preventing accelerated wear.

4. Improved Safety: Fewer catastrophic failures reduce workplace injuries and public safety incidents.

5. Typical ROI: Organizations report 300-500% ROI within 18-24 months of implementation.

Also Read : AI Data Governance: How to Build Secure, Ethical, and Compliant Systems

Conclusion

AI predictive maintenance is revolutionizing how industries manage critical infrastructure, delivering up to a 73% reduction in failures while optimizing costs, uptime, and safety. By leveraging machine learning, IoT sensors, and predictive analytics, organizations can move from reactive repairs to proactive maintenance with measurable ROI. Choosing Amplework ensures access to proven custom AI solutions, expert support, and seamless integration with existing systems, helping enterprises implement predictive maintenance effectively and achieve operational excellence across manufacturing, energy, utilities, and transportation sectors.

sales@amplework.com

sales@amplework.com

(+91) 9636-962-228

(+91) 9636-962-228